New Business

What Is Metallic Sodium Dispersion (SD)?

Our metallic SD consists of fine particles of metallic sodium dispersed into mineral oil and boasts superiority in terms of safety, handleability, and reactivity.

Drawing on a longstanding track record in handling this material, we are developing new metallic SD-related technologies.

Is Metallic SD Dangerous?

Most organic chemists and students in this field have performed experiments involving metallic sodium at some time or another. Metallic sodium is mainly used as a reductant in such processes as solvent dehydration, Birch reduction, and alkoxide synthesis.

1. How to Use Metallic Sodium

Usually, sodium is stored in the form of an ingot or wire that is kept submerged in oil.

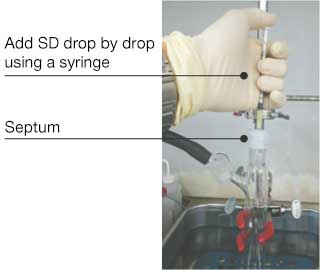

A typical example of the process involved in using sodium goes like this:

①Procure a piece of sodium; ②shave off its oxidized surface; ③cleanse the piece with hexane or a similar chemical; ④measure its mass; and ⑤add it to the prepared solution to obtain a reaction

As it is impossible to completely remove the oil from the surface of the sodium, its measured mass necessarily includes oil, making it difficult to accurately assess how great a mass of sodium actually being used.

Therefore, the amount of sodium being added for reaction must always be in excess of the theoretically required volume. That is also why immediately after a reaction has been completed, deactivation measures must be executed.

2. Dangers Associated with Sodium Deactivation

Methods for deactivating sodium include incrementally inserting it into cooled alcohol that is, in turn, enclosed in a vessel filled with inert gas. However, such methods entail the risk of a runaway reaction. During such dangerous operations procedures must be constantly monitored, which, in turn, results in higher personnel costs.

Because of these factors, the use of sodium in chemical reactions has been losing popularity in recent years.

3. What about Magnesium or Lithium?

Other materials used as reductants in organic chemistry include magnesium and lithium.

| Magnesium | Used in flake form to prepare a Grignard reagent. Although magnesium is an excellent reductant, it also carries a high risk of runaway reaction. Because of this, the industrial use of magnesium requires a significant accumulation of technological capabilities and expertise, and only a handful of domestic companies have succeeded in commercialization. |

|---|

| Lithium | Various organolithium compounds are currently in use. For example, butyllithium is used in synthetic rubber production, while lithium diisopropylamide (LDA) is used to manufacture pharmaceuticals. However, the volume of lithium being used is rapidly growing due to the recent popularization of lithium ion batteries, resulting in a surge in lithium market prices. |

|---|

Taking the above factors into account, there have been growing calls for a new reductant that can be handled in a liquid form like a Grignard reagent or an organolithium compound while being superior in terms of safety and reactivity.

What Is Metallic Sodium Dispersion (SD)?

Our metallic SD, or simply SD, consists of metallic sodium dispersed into oil in the form of fine particles approximately 10µm in diameter.

To date, we have been manufacturing metallic SD for use as a dechlorinating agent supporting the PCB decomposition process.

| Metallic sodium | SD | ||

|---|---|---|---|

| Outward appearance | Ingot, block, etc. | Gray slurry | |

| Usage | Laboratory use | Shave off the oxidized film that forms on the surface and cleanse it with a chemical like hexane before use. |

|

| Industrial use | Manually cut off a piece of ingot and place it into a reaction chamber. In order to secure sufficient reactivity, the volume of sodium must be in excess of the theoretically required volume due to the smaller specific surface areas of the ingot. A deactivation process is thus required despite the inherent danger of carrying one out. | Operators are not asked to directly handle sodium as SD can be supplied to the reaction vessel via a pipe. Moreover, due to the larger specific surface area of the particles, reactions can be executed at nearly theoretical volumes. This, in turn, makes it easier to deactivate sodium after reaction. | |

| Usage temperature | Often used at temperatures above a melting point (98°C) | ||

How to Purchase SD samples

For inquiries about metallic SD

To order SD samples, please fill out and send the following form.

Our staff in charge of ordering will contact you.