HOME > Environmental Restoration Projects > PCB/Dioxin Treatment (Detoxification) > Low concentration PCB Contamination Treatment Technology (Hydrodechloridation Refining Process = HDR Method)

PCB /Dioxin treatment (detoxification)

Kobelco Eco-Solutions is now struggling to launch the treatment business for low concentration PCB contaminated electric equipment as soon as possible.

- Total treatment system for low concentration PCB contaminated electric equipment

-

In 2002, it was revealed that some electric equipment including transformers considered to use no PCB contained insulating oil contaminated with PCB of several mg/kg to several dozen mg/kg. The number is estimated to be more than 1,200,000 in the whole country. (Source: Environment Ministry "Guideline for the Treatment of Waste Electric Equipment that Contain low concentration PCB Contaminated Oil (Incineration Disposal)")

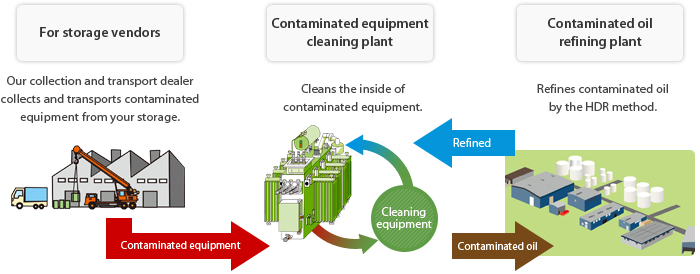

For those millions of waste electric equipment contaminated with low concentration PCB, Kobelco Eco-Solutions takes back such contaminated equipment and low concentration PCB contaminated oil from safekeeping enterprises, and works through the establishment of the business model that combines the following two businesses:

- Cleaning business that removes PCB from contaminated equipment by circulation of insulating oil inside of the equipment.

- Refining business that chemically decontaminates insulating oil used for cleaning and low concentration PCB contaminated oil by HDR method (Hydro Dechlorination and Refining) to produce refined oil.

Our goal of business model

Features of This Business Model

-

Economy

- Cost of low concentration PCB contaminated oil treatment by HDR method is affordable compared to incineration disposal.

- The quality of refined oil produced by HDR method is equivalent to that of new insulating oil and affordable.

- As treatment cost for small-size transformer, the cleaning treatment combined with HDR method is lower than the treatment by incineration disposal of whole transformer.

-

Utilization of Resources

Utilize resources by recycling contaminated oil as cleaning oil. -

Reduction of CO2

Emission of CO2 can be drastically reduced compared to incineration disposal. Emission of CO2 can be reduced 3 to 4 ton per insulating oil of 1ton. (Our trial calculation)

Low concentration PCB contaminated waste oil treatment technology

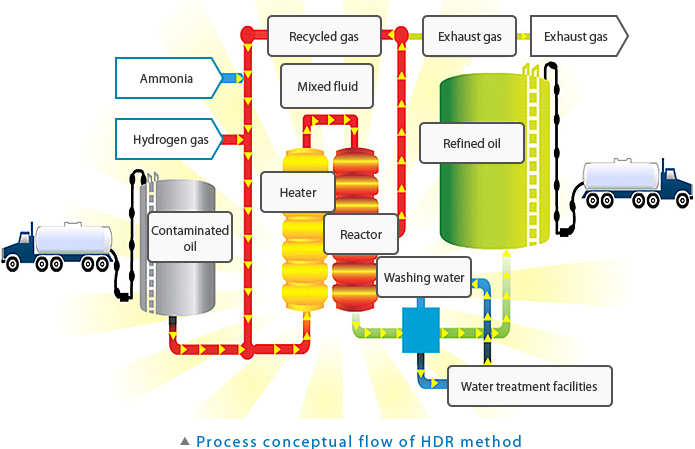

HDR method is the technology that decomposes and detoxifies low concentration PCB contained in insulating oil without spoiling insulation performance by hydrogenation reaction widely adopted in the oil refining industry, and also removes the impurities such as nitrogen to recycle insulating oil deteriorated by oxidation. In December 2009, we acquired the technical evaluation as one of the PCB treatment technology from the national committee (PCB Treatment Technology Research and Exploratory Committee) jointly with Hydrodec Group plc (Australia) that developed this technology.

In this detoxification treatment method, hydrogen gas and ammonia are added to low concentration PCB contaminated oil under the environment with hydrogenation catalyst. Then dechlorination is performed on the oil at about 300 to 320°C and 3.4MPa. Harmful residual products, exhaust gas, and wastewater are not produced in this method.