Cooling Tower

Gazing at the future, Kobelco Eco-Solutions’ cooling tower system

We are a top-tier cooling tower manufacturer

boasting a track record of more than 5,000 installations in Japan and overseas.

The cooling tower was originally developed in order to reuse valuable water after an enormous amount of groundwater had been used for industry to make land subsidence a social problem. It can be considered as a "water chiller" using natural forces. The cooling tower truly contributes to water resource recycling. We launched sales of the cooling tower products since 1962 and have accumulated experience in various arenas such as chemical plants, iron-manufacturing plants, power stations, regional air-conditioning facilities, among the others. We have shipped over 5,000 units in over 40 countries so far, leading the large-scale cooling tower segment. Recently, the cooling tower has been highly evaluated to reduce the urban heat islands. We are constantly aiming at green manufacturing.

Mechanisms

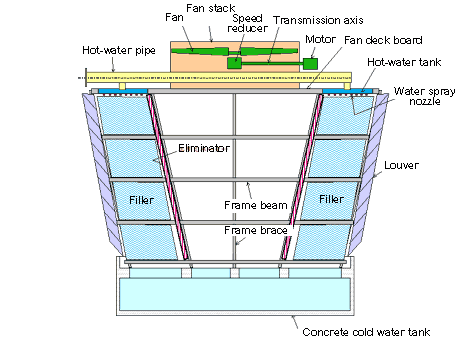

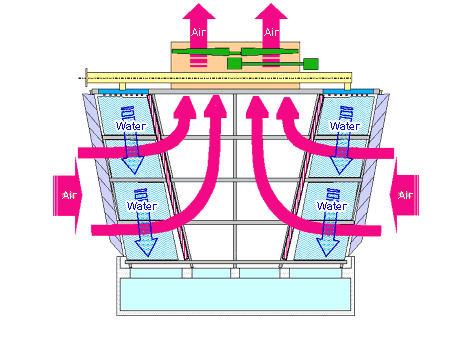

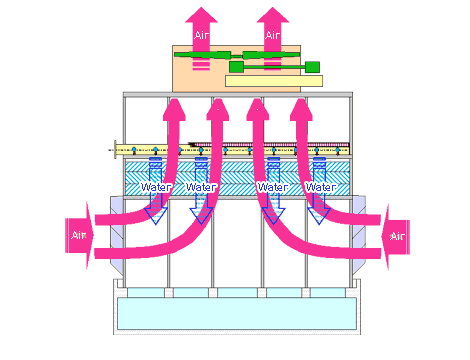

Cross Flow Cooling Tower

This type of cooling tower is called “cross flow” because air contacts water in a cross pattern. The cooling tower inhaling air from both sides is called “double-cross flow type” (shown in the figure to the right) and the cooling tower inhaling air from a single side is called “single-cross flow type.”

Advantages

- Removing foreign materials and cleaning are easy because the hot-water tank at the top of the tower is open.

- Inspection is easy because the filler can be visually checked from the side of the cooling tower.

- Inspection of the inside of the tower is available during operation.

- The fan power is lower than the counter flow type.

- The noise level near the tower is lower than the counter flow type.

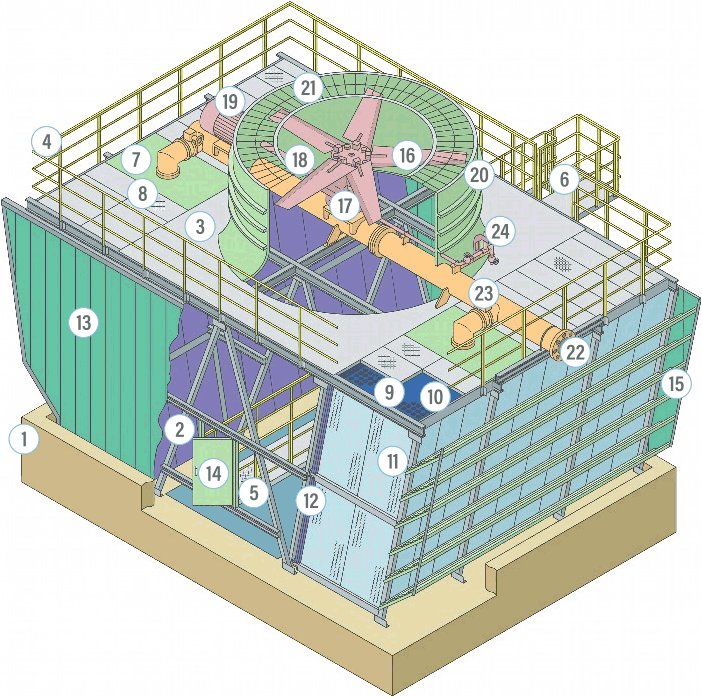

Cross flow cooling tower structure

Air and water flow of the cross flow type cooling

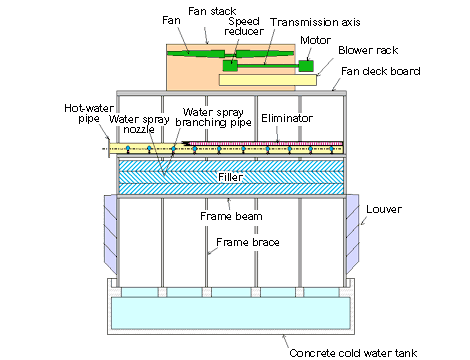

Counter Flow Cooling Tower

This type of cooling tower is called “counter flow” because air counters with water.

Advantages

- The pump lift can be lowered because the rising plumbing position can be lower than the cross flow type.

- Suitable for cold districts because less parts contact the outside air (e.g., filler).

Counter flow cooling tower structure

Air and water flow of the counter flow type cooling

Structure

| Parts name | Material | |

|---|---|---|

| 1 | Cold water tank | Concrete or FRP |

| 2 | Framework | Wood or molten galvanizing plate or FRP |

| 3 | Fan deck board | Wood or molten galvanizing plate or FRP |

| 4 | Handrail | Wood or molten galvanizing plate or FRP |

| 5 | Tower platform | Wood or molten galvanizing plate or FRP |

| 6 | Stairs of ladder | Wood or molten galvanizing plate or FRP |

| 7 | Water spray box | Wood or molten galvanizing plate or FRP |

| 8 | Hot water tank cover | Wood or molten galvanizing plate or FRP |

| 9 | Hot-water tank | Wood or FRP |

| 10 | Water spray nozzle | Polypropylene |

| 11 | Filler | PVC or polypropylene (film type, splash type) |

| 12 | Eliminator | PVC |

| 13 | Exterior plate/inside wall | PVC or FRP |

| 14 | Exterior plate door/inside wall door | Wood or FRP |

| 15 | Louver | FRP |

| 16 | Fan | FRP or aluminum |

| 17 | Speed reducer | |

| 18 | Transmission shaft | Stainless steel |

| 19 | Electric motor | |

| 20 | Fan stack | Molten galvanizing plate or FRP |

| 21 | Fan guard | Molten galvanizing plate |

| 22 | Hot water inlet pipe | Molten galvanizing plate or stainless steel |

| 23 | Flow adjuster valve | Cast iron |

| 24 | Oil feed pipe | Molten galvanizing plate or stainless steel |

Filler

Our state-of-the-art high-performance filler, based on technologies accumulated over a long period of time, addresses a wide range of water qualities.

Film type (PVC)

Splash type (polypropylene)