Waste Treatment/Recycling

Today, there is an urgent public call for reducing CO2 emissions to curb global warming. One answer to this call is the utilization of waste, which offers a valuable alternative energy source that can be used as fuel and is abundantly available from domestic sources.

As we look to the future, waste treatment facilities are expected to contribute to communities as regional energy centers that are helping vitalize local industry via the supply of energy derived from waste treatment. These facilities can also be utilized as our bases for disaster response at times of emergency.

We are developing technologies to support these facilities, pursuing breakthroughs in terms of energy creation and conservation while looking to reduce the volume of incineration residues with the aim of helping realize United Nations Sustainable Development Goals (SDGs). Furthermore, we are focused on developing facility automation technologies to help address issues arising from the lack of human resources available to take on waste treatment operations given Japan’s declining birthrate and graying society.

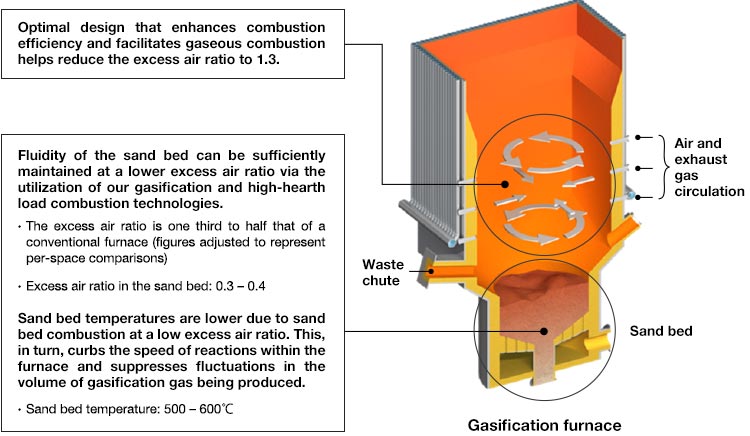

Gasification Combustion Furnace

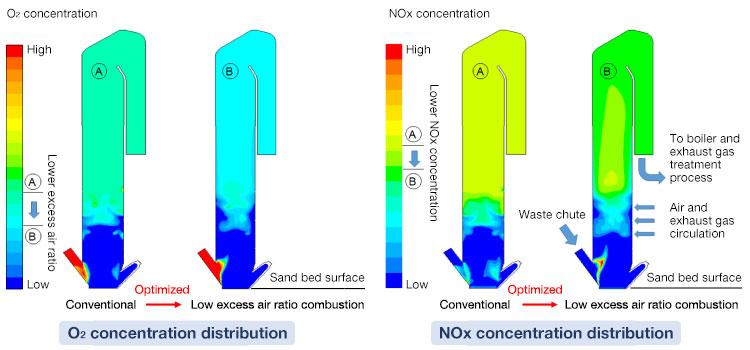

We have developed a gasification combustion furnace capable of maintaining combustion at a low excess air ratio via the application of gasification technologies accumulated in the course of developing gasification melting furnaces and combustion analysis technologies based on numerical simulation.

Having conducted a combustion analysis of the gasification furnace’s interior environment and optimized methods for facilitating air and exhaust gas circulation, we succeeded in curbing NOx generation solely via combustion adjustments at a low excess air ratio.

Development Background

In the course of developing the gasification combustion furnace, verification testing was carried out using actual equipment.

While upgrading the furnace design using such tools as numerical simulations, we optimized waste feeding methods and embarked on long-term technological verification. The simulation results were compared with findings from exhaust gas measurements using actual equipment to improve the computation model and enhance its accuracy.

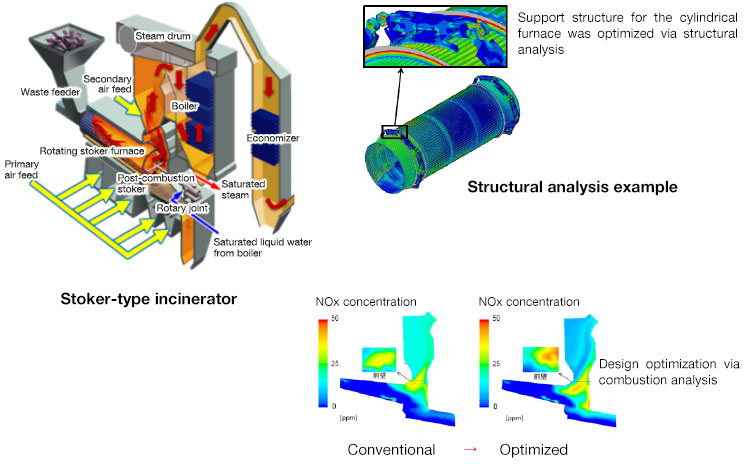

Stoker-Type Incinerator

A stoker-type incinerator consists of a cylindrically shaped furnace with boiler water pipes constituting the walls and boasts the following features.

①High durability

- The furnace is highly resistant to corrosion and abrasion because it rotates slowly at 1-2 rph and is cooled by high-temperature boiler water.

- Some furnaces have operated for more than 25 years without replacing the furnace body.

- The furnace is not refractory lined, which saves maintenance costs.

②Reliable operation performance

- The waste materials are fed into the furnace by its rotation on an inclined axis. Free of sliding and moving parts, the furnace has resistance to abrasion and jamming.

- The furnace has resistance to clinker problems because it is cooled to avoid clinker adhesion to the furnace wall.

③High combustion performance

- Complete combustion is achieved with less air supplied into the furnace because the swirling flame inside the cylindrical furnace facilitates the stirring and mixing of pyloric gases and combustion air.

- The furnace is designed to operate with a low air ratio (approximately 1.2) by using flue gas recirculation technology.

Development Background

Fundamental technologies for stoker-type incinerators were established more than 40 years ago. Since then, incinerators of this type have been used at home and abroad to incinerate municipal solid waste and industrial waste. Although the technology itself boasts long history and our business activities in this field largely reflect customer confidence in our track record, we constantly strive to deliver up-to-date, optimal solutions based on the verification of actual facility operations and new technology development.

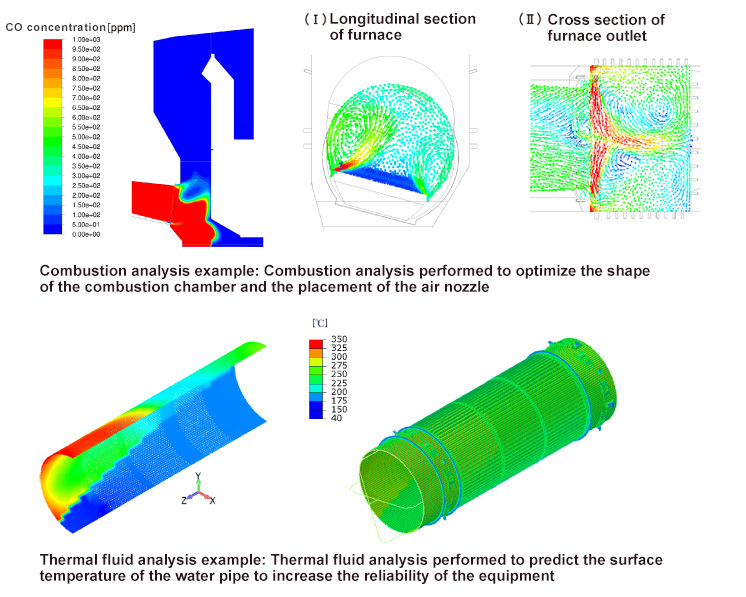

Previously, incinerator technologies could be verified only through practical demonstration tests; however, the introduction of latest simulation technologies allows for the virtual analysis of combustion, thermal fluid and structural factors at stages ranging from design through development, helping us to accelerate development.

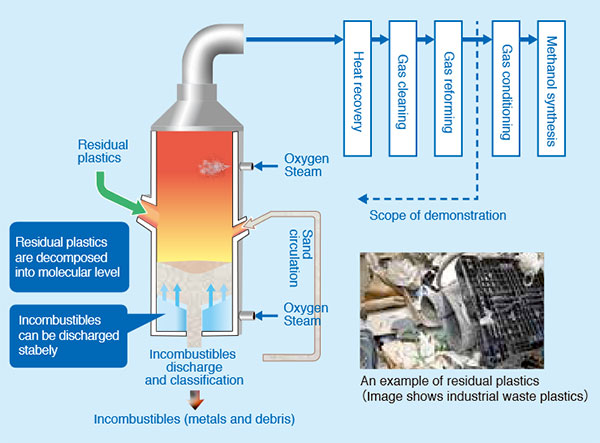

Waste plastics gasification to methanol

Residual waste plastics containing diverse impurities and materials are difficult to recycle so that they have been generally incinerated with or without thermal recovery, or placed in landfills. To achieve a sustainable circular and carbon neutral economy, chemical recycling of residual plastics is one of the solutions. The demonstration project for residual waste plastics gasification using a fluidized bed gasifier, which is one of our core technologies, is underway. One of the objectives of this project is to demonstrate the generation of syngas suitable for methanol synthesis.

Development Background

With this technology, for example, approx. 45,000 tons of methanol can be produced from the gasification of 60,000 tons of waste plastics, that is, approx. 100,000 tons of CO2 can be reduced with this technology, compared to the traditional methanol manufacturing method. We will keep trying to establish Japan's first chemical recycling process for synthesizing methanol through the gasification of miscellaneous waste plastics.

Accelerated carbonation technology (ACT)

Technology for reducing CO2 emissions through carbon capture and utilization/storage (CCUS) is attracting attention aiming at carbon neutrality by 2050. We are focused on the carbonation reaction, which involves the absorption and immobilization of CO2 by fly ashes, and more specifically the property wherein heavy metals are adsorbed into the fly ashes and become insoluble. Through this, we have developed the accelerated carbonation technology (hereinafter abbreviated as ACT) that allows the fly ashes generated in municipal waste incineration facilities to react with and immobilize CO2 generated in those same facilities. The ACT has been adopted in a commercial project*1 in favor of full-scale demonstration tests which proved (1) to accelerate effective utilization of CO2 and (2) to reduce consumption of chemicals for heavy metal stabilization, and construction of a plant is underway. We are working on to deploy this technology to diverse waste feedstocks which can be carbonized by utilizing the demonstration plant.

*1 The carbonation technology for fly ashes from municipal solid waste incineration was

adopted in the Fukui City Waste Treatment Facility

Development and O&M Project.

Development Background

The ACT contributes immobilization of CO2 by enabling a carbonation reaction to take place in a few minutes to a few tens of minutes, while it generally takes a few years for such a reaction to take place in nature. This technology features a simple process that allows the direct immobilization of CO2 without separating or collecting it in the exhaust gas.

We are currently working on the application of this technology to other types of wastes as well as the effective utilization/recycling of the wastes with immobilized CO2 and making efforts to increase the amount of CO2 immobilized, so that CO2 can be reduced in any fields.