Fluidized-Bed Gasification and Melting Furnace

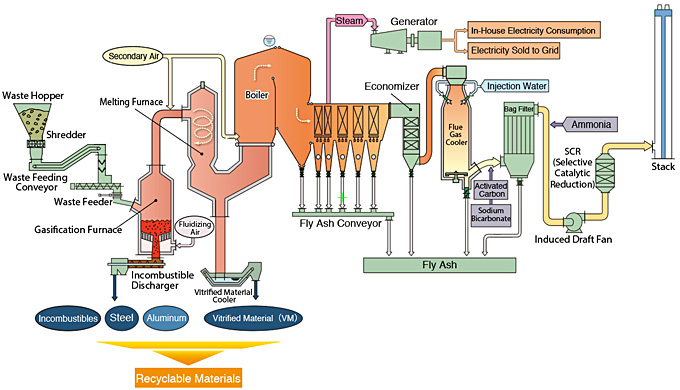

Process Flow Diagram

Overview

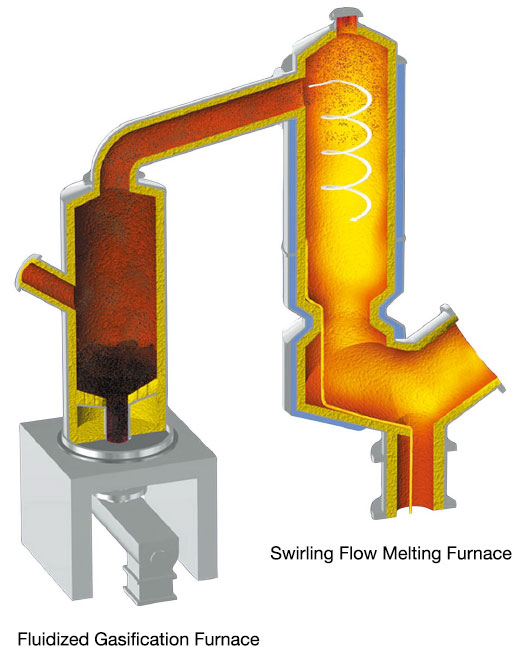

Our fluidized-bed gasification and melting furnace employs a high-temperature combustion and melting process in which waste is gasified in the fluidized sand layer and the gas then reacts with air, eventually producing Vitrified Material(VM) from melted ash. The facility is capable of performing this process without a fossil fuel supply, using only waste as an energy source.

Features

1. High Resource Recovery Efficiency

The facility recovers highly recyclable materials, such as steel and aluminum, from waste while producing Vitrified Material(VM) from incineration ash. This means that the combustion process leaves nothing to be disposed of and effectively renders all waste incineration residues into reusable resources, realizing “zero emission” status.

2. Superior Power Generation Efficiency

The lower volume of corrosive gas produced supports the use of a high-temperature high-pressure boiler that, in turn, allows for high-efficiency heat recovery for power generation.

3. High Treatment Capacity

Its ability to treat a variety of waste extends to waste once disposed of in landfills, enabling the reclamation of final disposal sites.

Examples of highly recyclable resources

-

Steel

-

Aluminum

-

Vitrified Material(VM)

Examples of Vitrified Material(VM) Utilization

-

As an ingredient in mixed asphalt

-

As an ingredient in concrete blocks used for slope reinforcement

-

As a backfill material

Examples of Our Track Record

| Facility name | Sagamihara City Minami Waste to Energy & Recovery Plant |

|---|---|

| Treatment capacity | 525t/day (175t/24h x 3 lines) |

| Power generation capacity | 10,000kW |

| Completion | March 2010 |

| Facility name | High-Efficiency Waste Incineration Power Generator (Kofu Kyoto Clean Center) |

|---|---|

| Treatment capacity | 369t/day (123t/24h x 3 lines) |

| Power generation capacity | 8,050kW |

| Completion | March 2017 |

| Facility name | Sennan Clean Center |

|---|---|

| Treatment capacity | 200t/day (100t/24h x 2 lines) |

| Power generation capacity | 3,200kW |

| Completion | March 2017 |

| Facility name | Kamiina Clean Center |

|---|---|

| Treatment capacity | 118t/day (59t/24h x 2 lines) |

| Power generation capacity | 1,990kW |

| Completion | March 2019 |