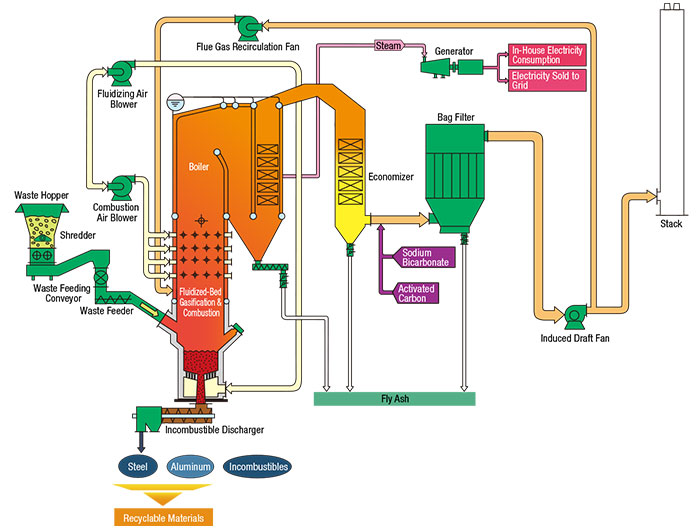

Fluidized-Bed Gasification & Combustion

Process Flow Diagram

Overview

Our fluidized-bed gasification furnace employs fluid sand to gasify and a relatively low volume of air to efficiently incinerate waste, which enables the downsizing of plants.

Features

1. High Power Generation Efficiency

The lower volume of corrosive gas produced supports the use of a high-temperature high-pressure boiler that, in turn, allows for high-efficiency heat recovery for power generation.

2. Superior Resource Recovery Efficiency

The fluidized bed-type furnace is capable of recovering good-quality iron, aluminum and other valuable metallic resources from waste.

3. Versatile

The facility treats a variety of waste, ranging from such low-calorie waste as sludge to plastics and other high-calorie waste in a stable manner.

Examples of Our Track Record

| Facility name | Hatsukaichi Energy Clean Center |

|---|---|

| Treatment capacity | 150t/day (75t/24h x 2 lines) |

| Power generation capacity | 3,140kW |

| Completion | March 2019 |

| Facility name | New Tate Clean Center (tentative name) |

|---|---|

| Treatment capacity | 160t/day (80t/24h x 2 lines) |

| Power generation capacity | 4,440kW |

| Completion | September 2022 |