List of product

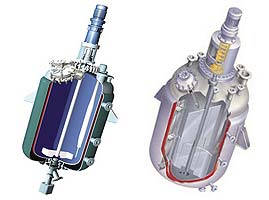

Glasslined Reactor

Stainless Steel and Special Metal Reactor

We are supporting manufacturing basics such as high-purity and high-quality of product and safety in the manufacturing, energy saving and streamlining in the fields of pharmaceutical, fine chemical and electronic material, etc.

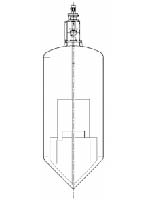

Multi Reactor

We have a lineup of glasslined reactor for research and trial production.

Impeller is easily-exchangeable to achieve multi-purpose operation.

The workload can be reduced by selecting options such as ferrule type quick opening & closing device and lifting & lowering device.

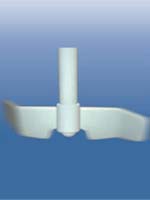

Glasslined General-Purpose Mixing Impeller “TWINSTIR”

This impeller is developed as a mixing impeller to replace the conventional three-blade retreat impeller.

This high functional mixing impeller handles both needs of contamination-free and low volume agitation which have been incompatible with the conventional mixing impeller.

Highly-Efficient Multifunctional Mixing Impeller “FULLZONE”

Mixing impeller which enables efficient mixing in the significantly wide viscosity range generating a groundbreaking flow pattern by arranging two wide paddles vertically crosswise.

Excellent mixing performance is realized for liquid-solid and liquid-liquid agitation.

Frictionless Clean Reactor “SWINGSTIR”

The circulation agitating style and non- rotating seal (flexible seal ) enabled to less contamination clean agitation.

High Density Liquid Mixing Impeller “LOGBORN”

LOGBORN extended its capability to the wider density range than the application limit of the conventional ribbon impellers.

LOGBORN with baffles has the similar flow pattern as the original type and can mix wide range of liquid from low density to 1,000 Pa·s successfully.

Ginjoshu Sake Tank “FULLZONE”

Uniform blending agitation without damaging unrefined sake. FULLZONE impeller realized uniform temperature control for entire unrefined sake.

Beer Yeast Tank “FULLZONE”

The FULLZONE impeller specifically developed for beer yeast fermentation tanks.

Various capabilities required for beer yeast fermentation are pursued.

Glasslined Assembly Mixing Impeller “Cryo-Lock”

This mixing impeller is realized by our unique “cooling fit” technology.

Contamination at the vessel flange part can be prevented as vessel flange is not required for FULLZONE and for an anchor impeller.

Manhole for Glasslined Equipment “Clampless Manhole”

The cover can be tightened and opened solely with the operation of the central handle.

Opening and closing time is drastically shortened compared with the conventional clamped manholes.

The spring balance equipment is attached to enable smooth cover opening and closing.

Manhole for Glasslined Equipment “E-Manhole”

With no peephole rising, the field of view is wider and the washability is improved.

Thanks to the O-ring in the seal part, only few clamps are required and gasket adjustment is not required.

Glasslined pH Measurement System “Glass Sensor pH”

Glass sensor pH has an electrode lined with pH glass.

Excellent in mechanical strength, it can be used continuously for a long time under severe conditions such as high-temperature and high-pressure.

High-Sensitivity Thermometer “Glass Sensor ST”

The entirely glasslined thermometer has the responsiveness equivalent of the thermometer with a tantalum chip.

Furthermore, it is easy to detach and is explosion-proof as the previous sheathed resistance thermometer sensor.

Glasslined Discharge Valve “Clean Flush Valve”

As the valve head top comes level with the vessel bottom at the close position, stagnant liquid is reduced. A large handle improved the operability. Weight is also reduced through a structural review.

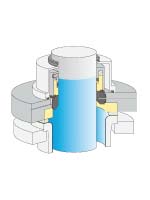

“Non-Contacting Seal” for Glasslined Equipment

Non-contacting seal has no sliding part because the seal ring floats by supplying N2 gas to the sealing surface from the seat.

Thus it makes this seal maintenance-free.

Electrically Conductive Gasslined “ECOGL® Ⅱ”

World first glass-lining which safely discharges the static electricity generated inside a reactor by the electrically conductive glass lining without losing the inherent glass function.

Low Metal Effluence Gasslined “9500”

This glass is developed by restudying glass composition to improve corrosion resistance and decrease the melting out of metal ion.

(melting out of Na ion decreased to one-tenth of the standard glass)

High Thermal Conductivity Glass

〜 9000HTⅡ & HYX Series 〜

9000HTⅡis high thermal conductivity glass by uniforming glass thickness and appling high thermal glass on the top coat.

HYX, which is hybridized 9000HT and ECOGLⅡ, achieves both improvement of thermal conductivity and anti-static function.

Beavertail BS®

The function of blowing or sampling is added to the conventional baffle with a thermometer.

The wetted parts, including the inner surface of the insertion tube is metal-free because of the glasslining.

This baffle makes it possible to simplify the nozzle orientation because blowing and sampling can be operated in one nozzle.

Ferru-cap

We have a lineup of hand holes for glass lining equipment that have a ferrule mechanism to make it easy to open and close.

Tank for Industrial Food

We have been manufacturing glasslined equipments as our main products since our establishment in 1946 and have been contributed to brewing industry such as sake, beer, wine, distilled spirit and whisky.

We continue to satisfy various needs.

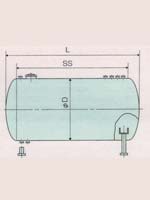

Tank for Chemical Industry

With our standard glass 9000, the tank is ideal to store liquid which is corrosive, adhesive, or susceptive to contamination by metal ion.

Glasslined Shell and Tube Heat Exchanger

With our standard glass 9000, the heat exchanger is excellent in corrosion resistant, non-adhesiveness and washability.

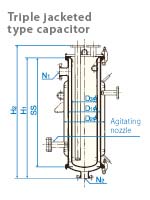

Glasslined Multiple Jacketed Type Heat Exchanger

With our standard glass 9000, the heat exchanger is excellent in corrosion resistant, non-adhesiveness and washability.

New Glasslined Multiple Conical Compact Condenser

Vertical and space-saving glasslined Condenser

GH Condenser

Compact and highly efficient condenser that combines a glass lining vessel with a highly corrosion resistant metal coil.

Glasslined and Nickel Alloy Hybrid Heat Exchanger “GMX”

Combining glass-lining and nickel alloy, the heat exchanger was downsized.

This heat exchanger was developed by the partnership between Kobelco Eco-Solutions and Mitsubishi Materials Corporation.

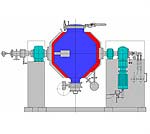

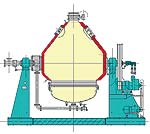

Vessel Rotary Mixing Dryer “Conical Dryer CDB®”

Maximum amount charged: 29,000 L

By rotating the vessel, gentle mixing and vacuum drying are realized.

Simple structure and excellent washability comply GMP.

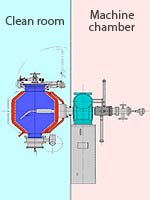

Vessel Rotary Mixing Dryer “Conical Dryer C-CDB®”

Maximum amount charged: 650 L

Cantilever-type conical dryer.

Machine body and drive part of this mixing dryer can be separated into inside and outside a clean room and ideal for GMP specifications.

Vessel Rotary Mixing Dryer “N-CDB®”

This conical dryer with no suction tube is clean and easy to washing.and that Non –metallic gasslined conical dryer is also developed.

Vessel Rotary Filter/Dryer “Conical Dryer with Filtration Function”

Maximum cake capacity: 3,000 L

Can be manufactured as all glasslined. It can process large quantity of products which do not have resistance against contact with metals.

Freeze Dryer 〜 RHEOFREED 〜

A new mixing-type freeze-dryer that incorporates a container rotation mechanism that is not available on tray dryer. It achieves shortening of drying time and homogeneity.

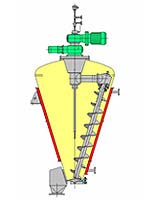

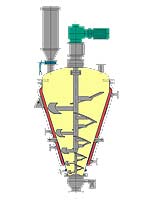

Planetary Motion Mixing Dryer “SV Mixer”

Maximum amount charged: 15,000 L

Rotating and revolving screw impeller gives the contents 3D motion to mix and vacuum dry gently and efficiently.

Heated impeller type is added to the lineup to contribute drying time reduction!

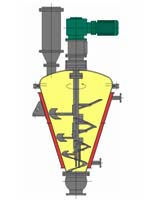

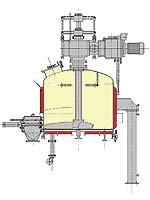

Vertical Mixing Dryer “PV Mixer”

Maximum amount charged: 10,000 L

Product can be circularly mixed thoroughly by rotating the special mixing impeller with the multistage pitched blade paddle.

Uniform mixing and drying is achieved with less clumping by cracking aggregates at the paddle edge part.

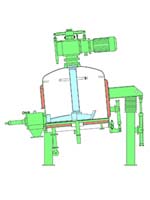

Vertical Filter/Dryer “PV Mixer with Filtration Function”

Maximum cake capacity: 3,000 L

Ideal to process large quantity of highly filterable slurry.

Powder which tends to agglutinate can be mixed and dried uniformly in short time by giving strong shearing force.

Multifunctional Filter/Dryer “Filter/Dryer”

Maximum cake capacity: 1,860 L

Basic type of filter/dryer and ideal to process slurry of low filterability.

Entire discharge type realized 99.9 % discharging efficiency.

Entire Recovery Type Filter/Dryer “Filter/Dryer”

Maximum cake capacity: 1,860 L

99.9 % discharging efficiency is realized.

Glasslined Filter (Clamp Type & Clampless Type)

The number of clamps of the conventional filter has been drastically reduced and work time for attachment and removal can be shortened.

We also have a lineup of "clampless types" that eliminate the necessity of clamps by opening and closing the filter plate with hydraulic jack.

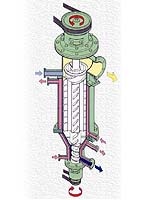

Film Evaporator for Low Viscosity Liquid “WIPRENE®”

Concentrated liquid in gravity flowing viscosity range can be treated.

Forming a uniform thin film on the entire evaporation surface, higher heat transfer coefficient can be obtained.

Compact design and small pressure loss on the evaporation surface and condensation surface enable high vacuum operation.

Available for gasslined.

Thin Film Evaporator for High Viscosity Liquid “EXEVA®”

EXEVA can remove volatile products, solvent and monomer from ultra high viscosity substance of 100,000 poise which does not flow with gravity.

After the ultra high viscous product is formed into a very thin film with mechanical force to remove volatile substances under vacuum, the product can be discharged directly under atmospheric pressure.

Process Equipment Division, Kobelco Eco-Solutions Co., Ltd.

- Osaka Branch

- Midosuji Mitsui Building,

- 1-3, 4-chome, Bingomachi, Chuo-ku, Osaka, 541-8536, Japan

- TEL +81-6-6206-6161

- FAX +81-6-6206-6758