Process Equipment

We accommodate diverse user needs by taking advantage of agitation and other technologies, with our glass-lined equipment as our mainstay product.

To fulfill our responsibilities as a top-notch glass-lined equipment manufacturer we constantly strive to enhance our development capabilities related to the creation of distinctive and unique products of unparalleled quality and to improve the manufacturing technologies that ensure continued stable production.

Hybrid Glass-Lined Equipment HYX Series

Glass-lined equipment has long been used in a range of chemical industry fields that require high-purity materials. For such purposes, glass lining, a compound of glass and steel with high corrosion resistance, is considered ideal.

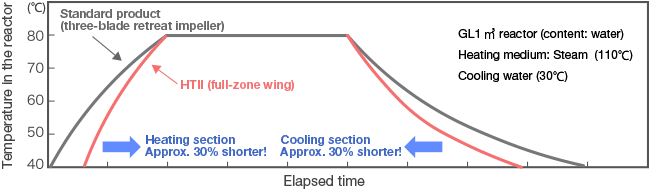

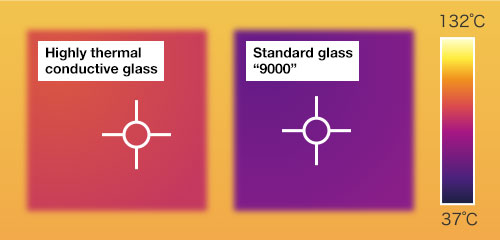

Our latest products include the high thermal conductivity glass 9000HT II, which helps improve productivity and reduce manufacturing costs by heating up in a shorter time due to its enhanced thermal conductivity.

Moreover, we have developed hybrid glass-lined equipment that combines the above mentioned high thermal conductivity glass with the electrically conductive glass ECOGL®Ⅱ, which is greatly sought after by users and is capable of preventing electrostatic damage, and PPG, a pharmaceutical glass that is a product of Pfaudler Germany.

Hybrid Glass-Lined Equipment HYX

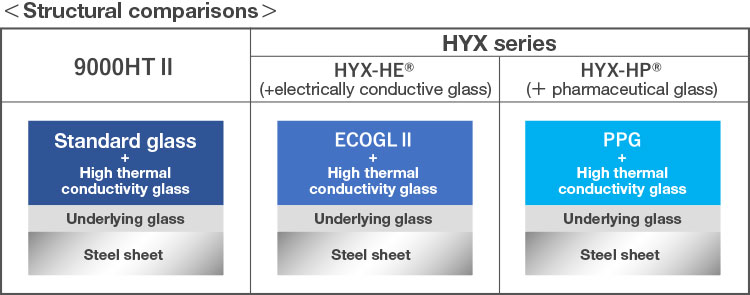

Although the 9000HT Ⅱ glass system has a surface layer of “9000 glass,” the HYX series has multiple functions due to the incorporation of electrically conductive ECOGL®Ⅱ or pharmaceutical PPG glass in its surface layer. An overview of the structure of these products is presented below.

In addition, the high thermal conductivity glass 9000HT Ⅱ is capable of shortening time spent on heating and cooling.

Development Background

In terms of thermal conductivity, glass is generally inferior to steel. Accordingly, conventional glass-lined equipment has long used a compound of glass and steel to counter issues arising from low thermal conductivity.

Tackling this problem, we have taken advantage of our unique technologies associated with determining glaze and glass composition as well as the production of multi-layered structures utilizing our integrated production system encompassing various processes ranging from glass melting to lining. Thanks to these distinctive strengths, we were able to create the high thermal conductivity glass 9000HT Ⅱ. We also developed hybrid glass-lined equipment that combines 9000HT Ⅱ with ECOGL®Ⅱ, an electrically conductive glass that is much appreciated by users for its resistance to electrostatic damage, and the pharmaceutical glass PPG.