Environmental Restoration

Persistent organic pollutants, or POPs, are extremely toxic and do not readily decompose in the environment. As it is feared that these substances negatively affect organisms via bioaccumulation, there is a growing call for international countermeasures to address risks arising from their movement and emissions.

Answering this call, we are developing technologies supporting countermeasures to help mitigate the environmental impact and risks associated with POPs.

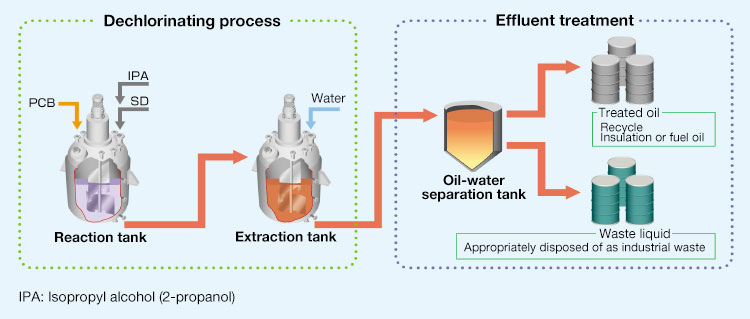

An Organic Halogen Treatment Process Employing the Metallic Sodium Dispersion Method (SP Process)

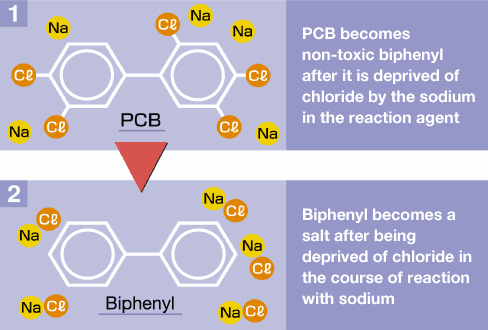

With the aim of dechlorinating and detoxifying organic chloride compounds, this technology employs a reaction agent consisting of fine particles of metallic sodium dispersed into oil (metallic sodium dispersion or “SD”) and a reaction accelerator that replaces desorbed chlorine with hydrogen. This SP process has been tested for the treatment of PCBs, dioxin, BHC, chlordane and other POPs and is recognized as a safe detoxification technology for these substances.

Currently, discussion is under way regarding the applicability of this technology in the treatment of organic halogen (a substance that has recently been designated by the Stockholm Convention on POPs as requiring regulation) based on its proven ability to achieve a target decomposition ratio of 99.999% stipulated under technical guidelines of the Basel Convention.

Laboratory testing of POPs detoxification process

Key reactions taking place in PCB dechlorinating process

Development Background

The SP process, a technology for treating PCB-contaminated oil, has been developed by Canada-based Powertech.

Based on this process, we have established a technology capable of treating high-concentration PCBs in low-temperature environment via the exploration of reaction conditions that satisfy criteria stipulated under Japan’s relevant laws, which are the world’s strictest regulations of this kind. Our technology is currently used by a number of private companies and government-sponsored collective disposal facilities thanks to the success of our efforts to establish methods for treating reaction byproducts and those for swift toxicity analysis and evaluation. In this way, we are contributing to progress with PCB detoxification.